How does glass through Hole (TGV) technology improve the integration and performance of chip packages

Nowadays, electronic products have higher and higher requirements for performance and integration, and traditional chip packaging technology is slowly falling behind and cannot meet the needs of the market. This is where TGV (Through Glass Via) technology comes in! This can bring great changes to the field of chip packaging, so that integrated circuits have a great improvement in design and performance. Next, let's take a good look at the basic principles of this TGV technology, application advantages, and its impact on the future direction of chip packaging.

Let's start with the first principles. TGV technology is mainly used to punch small holes in high-precision glass substrates, so that electrical connections can be achieved. Compared with traditional packaging materials, glass materials have many advantages, such as high mechanical strength, low moisture absorption, and particularly good chemical stability. With these features, the TGV can smoothly transmit signals in high-frequency, high-speed electronic components.

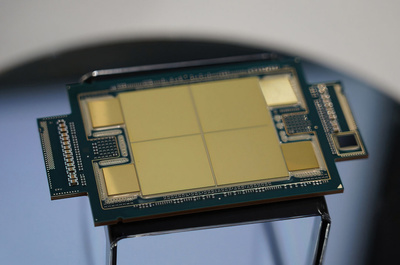

In practice, TGV technology consists of several key steps. A glass substrate must be selected and micrometer-scale through-holes cut into it, which can be done by precision lithography and etching processes. The through hole is then filled with a metal material such as copper or nickel, and the electrical connection is complete. This set of operations not only ensures the stable transmission of signals, but also minimizes the package space, creating conditions for the high-density integration of EZFF815Q906L chip.

Let's talk about improving chip package integration. TGV technology has a special place, that is, it can greatly improve the integration of the chip package. The traditional packaging technology is limited by the material characteristics and design, the circuit can play a limited space. But TGV technology is different, opening a lot of electrical connection channels on the glass substrate, which can reduce the package area, so you can integrate more functions on a chip.

For example, TGV technology can be used in 3D package structures to stack chips with different functions on top of each other to form a more complex and efficient overall solution. This layered design not only improves integration, but also reduces signal transmission delays and improves overall performance. In this way, electronic products can be smaller and smaller at the same time, the performance is still improving, which is in line with the trend of modern technology to pursue thin and efficient.

In addition, TGV technology is excellent for optimizing electrical performance. In the case of high frequency applications, signal integrity and delay are key factors. The traditional packaging technology is often affected by parasitic inductance and capacitance during signal transmission, and the signal will become weak and distorted. But the TGV technology's use of glass materials, coupled with a fine through-hole design, greatly reduces these adverse effects.

The low dielectric constant of glass means that the signal attenuation is small when transmitting high frequency signals. In addition, the TGV's short through-hole connection shortens the transmission path and reduces transmission latency. These advantages make TGV technology especially excellent in high-speed and high-frequency applications, and it is widely used in important fields such as data centers and 5G communications.

Let's talk about thermal management performance. When the chip works, it generates heat, and this heat sometimes acts as a barrier that limits the chip's performance. TGV technology is much better at thermal management than traditional packaging technology. The thermal conductivity of the glass material is better than that of many plastic materials, which can effectively disperse the heat generated during the operation of the chip. In addition, TGV technology enables a more compact package design with shorter and faster heat transfer paths.

By optimizing thermal management performance, TGV technology not only improves the working efficiency of the chip, but also prolongs the service life of the chip. This is an important competitive advantage in a market where durability and reliability are highly demanded.

Then there's manufacturing and cost-effectiveness. Although the manufacturing cost of glass substrate is relatively high, with the continuous progress of production technology, the production scale continues to expand, and the cost performance of TGV technology is slowly improving. Thanks to advanced lithography and etching techniques, the precision of the manufacturing process is greatly improved.

In addition, the degree of automation of TGV technology is also increasing, allowing production costs to be further reduced. The optimized manufacturing process makes TGV technology not only have advantages in performance, but also break through the traditional packaging technology in cost control. This change has made the TGV more widely used and gradually become the standard choice in the middle and high-end market.

Finally, talk about the expansion of the application field. TGV technology, with its advantages in integration, electrical performance and thermal management, is beginning to emerge in a number of industries. In the consumer electronics sector, products such as smartphones, tablets and ultra-thin notebooks are increasingly adopting TGV technology to enable thinner, lighter designs through high-density packaging. In automotive electronics, medical equipment, industrial control and other fields, TGV technology also shows great application potential.

With the rapid development of the Internet of Things and smart devices, the demand for high-performance and highly integrated chips will be more urgent in the future. This provides a broader market space for the promotion and application of TGV technology. It is conceivable that TGV technology will play its unique advantages in more electronic products and promote the development of the entire industry in a more efficient and intelligent direction.

您可能感興趣的產品

|

CP2725AC54TEZ | AC/DC CONVERTER 54V 5V 2725W | 6960 More on Order |

|

ULVT006A0X43-SRZ | MODULE DC DC CONVERTER | 8658 More on Order |

|

UNVT006A0X3-SRZ | DC DC CONVERTER 0.6-6V 6A | 4914 More on Order |

|

KHHD004A2S8R0841Z | DC DC CONVERTER 8V 34W | 5814 More on Order |

|

ULDT012A0X3-SRZ | DC DC CONVERTER 0.45-5.5V | 3978 More on Order |

|

HW010A0F1-SR | DC DC CONVERTER 3.3V 33W | 6444 More on Order |

|

HC006A6A1 | DC DC CONVERTER 5V 33W | 4320 More on Order |

|

EHHD006A0B41-SZ | DC DC CONVERTER 12V 72W | 7128 More on Order |

|

QW030AJ1 | DC DC CONVERTER +/-5V 30W | 5256 More on Order |

|

QW010A0A1 | DC DC CONVERTER 5V 50W | 5436 More on Order |

|

QHW075A71 | DC DC CONVERTER 5V 75W | 7092 More on Order |

|

MW010B | DC DC CONVERTER 12V 10W | 4500 More on Order |

|

LW015B1 | DC DC CONVERTER 12V 15W | 4698 More on Order |

|

JW030A8-M | DC DC CONVERTER 5V 30W | 3618 More on Order |

|

JBW030A1 | DC DC CONVERTER 5V 30W | 3726 More on Order |

|

HW050AF | DC DC CONVERTER 5V 3.3V 53W | 3598 More on Order |

|

ATH006A0X4 | DC DC CONVERTER 0.8-3.6V 21W | 4914 More on Order |

|

UVXS1212A0X3-SRZ | DC DC CNVRTR 0.6-5.5V 0.6-5.5V | 6030 More on Order |

|

APTH006A0X4-SRZ | DC DC CONVERTER 0.6-3.63V 22W | 2196 More on Order |

|

ATS030A0X3-SRHZ | DC DC CONVERTER 0.8-2.75V 80W | 2394 More on Order |

|

IND011SIP | DC DC CONVERTER 0.6-5.5V 11W | 8910 More on Order |

|

AXA010A0X3Z | DC DC CONVERTER 0.8-5.5V 55W | 606 More on Order |

|

EHHD006A0B41-HZ | DC DC CONVERTER 12V 72W | 11748 More on Order |

|

MDT040A0X3-SRPHZ | DC DC CONVERTER 0.45-2V 40A | 53760 More on Order |