Aluminum interconnect corrosion: a potential risk for integrated circuit stability

In today's era of rapid technological development, integrated circuit (IC), as a core component of electronic devices, has penetrated into all aspects of our lives. From smartphones to supercomputers, almost all modern electronic devices rely on high-performance integrated circuits. One of the seemingly trivial but crucial elements is the aluminum interconnect. The quality and stability of aluminum interconnect are directly related to the performance of integrated circuit, and the corrosion of aluminum interconnect is one of the important hidden dangers of integrated circuit reliability.

Basic characteristics of aluminum interconnects

Aluminum interconnect is an important channel connecting various components in the integrated circuit chip, responsible for the transmission of electrical signals. Because of its excellent conductivity and relatively low cost, aluminum interconnects became one of the early and still widely used materials. Aluminum material has good mechanical properties and easy workability, but it may cause corrosion problems in specific environments, affecting the electrical conductivity of the interface, and eventually leading to circuit failure.

Cause of corrosion

The corrosion of aluminum interconnects is mainly affected by many factors such as environment, material properties and current density. Environmental factors, such as humidity, temperature, and the presence of contaminants, can accelerate the corrosion of aluminum. It is easy to form a thin layer of alumina on the surface of aluminum. This layer of oxide film can play a protective role in normal circumstances, but in humid or corrosive environments, the oxide film may be destroyed, exposing the metal aluminum.

In addition, the microstructure and grain boundaries of aluminum materials also affect the occurrence of corrosion. Pure aluminum is more prone to corrosion than alloyed aluminum, and the grain size and orientation will affect the mechanical strength and electrical conductivity of aluminum. What's more, the risk of electrochemical corrosion increases significantly when the current density is too high. In the case of high current density, the surface of the aluminum interconnect may produce local overheating phenomenon, which not only promotes the corrosion of the metal, but also may lead to changes in the microstructure, leading to more complex failures.

Corrosion effect

Corrosion of aluminum interconnects can cause problems in several ways. First, the electrical conductivity decreases, making the signal transmission unstable, which is particularly obvious in high-frequency applications, which can lead to signal attenuation, distortion and other problems. In addition, corrosion will trigger an increase in contact resistance, further leading to rising power consumption and heat accumulation, which will affect the normal operation of the chip. Especially in the dense area of integrated circuits, the increase in local temperature may cause thermal runaway, and in serious cases will lead to chip burnout.

Moreover, the impact of aluminum interconnect corrosion is not limited to performance, but can also negatively affect the life of integrated circuits. Working in a corrosive environment for a long time, the stability of the aluminum interconnect gradually decreases, which may eventually lead to early failure of the equipment. Especially for aerospace, medical, communications and other areas with high reliability requirements, the corrosion hazards of aluminum interconnects are more important.

Preventive measure

In order to effectively prevent the corrosion of aluminum interconnects, many researchers and engineers are exploring a variety of feasible preventive measures. First,optimize the alloy composition of aluminum materials, by adding appropriate alloying elements, such as copper, silicon, etc., to improve the corrosion resistance of aluminum. Secondly, coating anti-corrosion materials is an effective solution. The application of protective coating on the surface of aluminum interconnect can not only prevent the intrusion of external corrosives, but also effectively extend the service life of the interconnect.

In addition, controlling the humidity and temperature of the working environment is key to reducing the risk of corrosion. When designing integrated circuits, moisture intrusion can be prevented by better sealing design and moisture-proof encapsulation materials. At the same time, for high current density applications, the peak and amplitude of the current are minimized to avoid current overload. In addition, a reasonable heat dissipation design also helps to reduce the temperature of the circuit during operation and reduce corrosion caused by overheating.

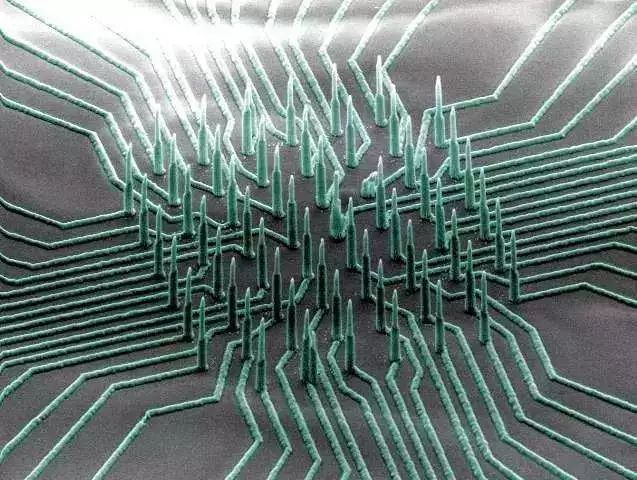

For the joint inspection technology, with the development of high-resolution microscopy, transmission electron microscopy (TEM) and scanning electron microscopy (SEM) and other technologies, can accurately monitor the corrosion of aluminum interconnects, as well as early detection of potential abnormal changes, conducive to timely maintenance and repair.

Exploration of emerging materials

With the emergence of many corrosion problems, the development of new interconnect materials has become an important direction for the development of integrated circuits in the future. The introduction of copper interconnection is one of the successful cases. Copper not only has better conductivity, but also performs better in corrosion resistance under appropriate processes. Although copper interconnects present many challenges in the manufacturing process, such as issues such as oxidation resistance and contact resistance, these technical obstacles are expected to be overcome in the future through innovative electronic materials and device designs.

Finally, the continuous progress of integrated circuit design, material science and engineering technology will reduce the impact of aluminum interconnect corrosion to a certain extent. With the continuous development of the industry, the stability of aluminum interconnects will also be more effectively solved, thus escorting our high-tech life.

您可能感興趣的產品

|

AMI-26B-20-3 | LINE FILTER 250VAC 20A CHASS MNT | 3780 More on Order |

|

AMI-29-30-6 | LINE FILTER 110/250VAC 30A CHAS | 6012 More on Order |

|

AMI-28-12-3 | LINE FILTER 110/250VAC 12A CHAS | 7812 More on Order |

|

AMI-28B-10-3 | LINE FILTER 110/250VAC 10A CHAS | 6318 More on Order |

|

AMI-M11E-1-6-D-2 | LINE FILTER 250VAC 1A CHASS MNT | 8658 More on Order |

|

AMI-M12U-6-20-B | LINE FILTER 250VAC 10A CHASS MNT | 8676 More on Order |

|

AMI-M12J-3-3-B | LINE FILTER 250VAC 3A CHASS MNT | 7092 More on Order |

|

AMI-29-10-3 | LINE FILTER 110/250VAC 10A CHAS | 5292 More on Order |

|

AMI-26A-12-3 | LINE FILTER 250VAC 12A CHASS MNT | 3870 More on Order |

|

AMI-M12J-3-3-C | LINE FILTER 250VAC 3A CHASS MNT | 6678 More on Order |

|

AMI-M11G-7-3-A | LINE FILTER 250VAC 3A CHASS MNT | 4014 More on Order |

|

AMI-M12X-1-15-C | LINE FILTER 250VAC 15A CHASS MNT | 8532 More on Order |

|

AMI-M12W-3-10-C | LINE FILTER 250VAC 10A CHASS MNT | 8982 More on Order |

|

AMI-23-8-3 | LINE FILTER 250VAC 8A CHASS MNT | 5346 More on Order |

|

AMI-29A-3-1 | LINE FILTER 110/250VAC 3A CHAS | 8406 More on Order |

|

AMI-M11UD-3-16-B | LINE FILTER 250VAC 3A CHASS MNT | 7920 More on Order |

|

AMI-M12R-3-2-B-1 | LINE FILTER 250VAC 3A CHASS MNT | 8388 More on Order |

|

AMI-M32A-10-16-E-2 | LINE FILTER 16A CHASSIS MOUNT | 2826 More on Order |

|

AMI-26-16-1 | LINE FILTER 250VAC 16A CHASS MNT | 6858 More on Order |

|

AMI-M11S-1-3-C | LINE FILTER 250VAC 3A CHASS MNT | 2736 More on Order |

|

AMI-B11AW1-13-4-B | LINE FILTER 250VAC 4A PCB | 4176 More on Order |

|

AMI-22-16-1 | LINE FILTER 250VAC 16A CHASS MNT | 3060 More on Order |

|

AMI-M11A-1-2-D | LINE FILTER 250VAC 2A CHASS MNT | 8784 More on Order |

|

AMI-21-3-3 | LINE FILTER 250VAC 3A CHASS MNT | 8424 More on Order |