Highly efficient protection, industrial robots cannot do without waterproof connectors

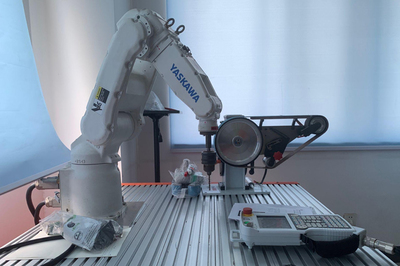

Under the general trend of the rapid development of modern industrial automation, industrial robots have become an indispensable part of the manufacturing industry with high efficiency and precision. With the continuous progress of science and technology, industrial robots have been widely used in many industries, such as automobile manufacturing, electronic assembly, food processing and other industries have their figure. If you want these industrial robots to work efficiently in a variety of environments, the application of waterproof connectors is too important. Next, let's talk about why waterproof connectors are important in industrial robots, and what are its related technical characteristics.

Let's talk about what is a waterproof connector. A waterproof connector is a device used for electrical connections that prevents moisture and other liquids from entering the connection points, thereby protecting electrical and electronic equipment from moisture, corrosion, and other external factors. Waterproof connectors generally have a special sealing design, but also the use of protective materials, can reach IP67, IP68 and other IP levels. These grades represent the depth of immersion the connector can withstand in a given time.

Look at the working environment of industrial robots. The environment in which industrial robots work is often dynamic and demanding, with conditions such as high humidity, high dust and temperature changes. For example, in food processing, robots must work in humid environments at all times. In automotive manufacturing, the HY57V281620GCT-H robot must work in harsh environments with large amounts of oil and possible liquid leaks. Therefore, choosing the right waterproof connector is crucial to ensure that these robots can operate safely and efficiently.

Let's talk about the technical characteristics of the waterproof connector:

The first point is the sealing performance. The most critical technical feature of the waterproof connector is good sealing performance. It uses high-quality sealing materials such as silicone, polyurethane and EPDM rubber to effectively block moisture and other contaminants. These materials are carefully designed to withstand not only momentary water pressure, but also long-term moisture intrusion, providing a stable electrical connection for the robot.

The second point is corrosion resistance. There are many types of chemicals and liquids in the industrial environment, so the corrosion resistance of waterproof connectors is also particularly important. Many waterproof connectors are either made of high-performance alloy materials or plastic materials and are treated with special coatings that can resist acid and alkali corrosion and high temperatures. This design ensures that the connector can always be used reliably in harsh environments.

The third point is high reliability and durability. The workload of industrial robots is generally very heavy, and vibration and shock are common things. Therefore, waterproof connectors must be designed with their seismic and tensile characteristics in mind. Many waterproof connectors use reinforced structural design, such as reinforced fixtures, and rubber pads, so that in the high-frequency operating state, the connector is not easy to loose and fail.

Fourth, connectivity in various forms. Different types of industrial robots have different requirements for electrical connections. Waterproof connectors have a variety of connection forms, such as plug sockets, circular connectors, square connectors, etc., can meet the needs of various application scenarios. Especially in some occasions that require frequent replacement of equipment or modules, the design that can quickly connect and disconnect can save a lot of time and improve work efficiency.

The fifth is temperature and pressure adaptability. Waterproof connectors must be able to adapt to the temperature and pressure range of industrial robots. Many waterproof connectors have been specifically designed and tested to operate at extreme temperatures, such as -40°C to +125°C, as well as high pressures. Due to this adaptability, it is also widely used in high temperature and high pressure environments such as welding and spraying.

Talk about the application of waterproof connectors.

In the field of automotive manufacturing, industrial robots often directly encounter a variety of liquids such as oil and coolant. The use of waterproof connectors can effectively ensure that the electrical interface of the robot is not corroded, so that the performance of the robot has been stable in long-term work.

In the electronics manufacturing industry, the application of waterproof connectors is also essential. Now that electronic devices are moving in the direction of miniaturization and precision, waterproof connectors can provide smaller interface options while also ensuring reliable signal transmission in wet environments.

In the food processing industry, health and safety is the first consideration. The waterproof connector is designed to meet sanitary standards, and its material and structure can be tightly closed to prevent bacterial growth and ensure safe operation.

What factors should companies consider when choosing waterproof connectors? There are many factors to consider, such as the IP level of the connector, the material, the connection form, the manufacturer and the cost. Although the price of a high IP connector may be higher, the reliability it brings and the maintenance costs it reduces can often save businesses a lot of money in the long run. Moreover, enterprises must also choose reputable manufacturers when purchasing, so as to ensure product quality and after-sales service.

Finally, talk about the future development trend. With the continuous development of automation technology, the industrial Internet of Things has also risen, and the future industrial robots will be more intelligent and networked. In this case, waterproof connectors must have higher performance, more intelligent design, in order to adapt to the changing industrial needs. This means that further research is needed in the fields of materials science, connected technology, intelligent monitoring, and so on, which is an inevitable trend.

Waterproof connectors are not only an integral part of industrial robots, but also the basis for their efficient operation and safety protection. In different industrial applications, whether the waterproof connector is selected well and used correctly is directly related to the stability and reliability of the robot system. Therefore, if the enterprise can fully understand its technical characteristics and application scenarios, it can be advantageous in the fierce market competition.

您可能感興趣的產品

|

480 | SMALL ARCADE JOYSTICK | 5526 More on Order |

|

419 | SWITCH KEYPAD 12 KEY NON-ILLUM | 9024 More on Order |

|

917 | RUGGED METAL ON/OFF SWITCH | 6498 More on Order |

|

1187 | SWITCH PUSHBUTTON SPST-NO WHT | 8802 More on Order |

|

3930 | SENSOR OPT REFLECTIVE RADIAL | 8766 More on Order |

|

2349 | REFLECTIVE IR SENSOR WITH 470 AN | 6066 More on Order |

|

4007 | ULTRASONIC DISTANCE SENSOR - 3V | 344 More on Order |

|

3828 | 5 ETAPE LIQUID LEVEL SENSOR WITH | 5526 More on Order |

|

3245 | THERMOCOUPLE TYPE-K GLASS BRAID | 3618 More on Order |

|

407 | ELECTROLUMINESCENT WIRE GRN 2.5M | 6552 More on Order |

|

445 | ELECTROLUMINESCN STRIP RED 100CM | 6660 More on Order |

|

1548 | ADDRESS LED STRIP SERIAL RGB | 5598 More on Order |

|

1934 | 7"" TFT DISPLAY 800 X 480 | 2556 More on Order |

|

1933 | 7"" TFT DISPLAY 800 X 480 | 2394 More on Order |

|

1743 | 3.2"" TFT LCD WITH TOUCHSCREEN BR | 6408 More on Order |

|

1816 | 10 SEGMENT LIGHT BAR WHITE | 2967 More on Order |

|

679 | DIFFUSED 5MM SLOW FADE FLASHING | 4644 More on Order |

|

498 | RGB BACKLIGHT NEGATIVE LCD | 8892 More on Order |

|

564 | POCKET INVERTER EL WIRE 4-AAA | 7182 More on Order |

|

1857 | SMALL 1.2 8X8 ULTRA BRIGHT SQUAR | 2790 More on Order |

|

1818 | LED MATRIX 8X8 SQUARE AMBER | 4608 More on Order |

|

2026 | 32X32 RGB LED MATRIX PANEL 5MM P | 5418 More on Order |

|

2276 | 64X32 RGB LED MATRIX - 6MM PITCH | 7542 More on Order |

|

1907 | DUAL ALPHANUMERIC DISPLAY - RED | 2736 More on Order |