KLA-Tencor introduces a new measurement system for cutting-edge integrated circuit device technology

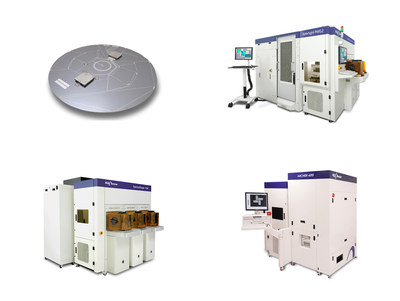

KLA-Tencor introduces four innovative measurement systems for the development and mass production of integrated circuit (IC) devices below 10 nanometers (sub-10nm) : The Archer 600 Stack measurement system, WaferSight PWG2 pattern chip geometry measurement system, SpectraShape 10K Optical Critical Dimension (CD) measurement system and SensArray HighTemp 4mm real-time temperature measurement system. These four new systems further broaden KLA-Tencor's exclusive 5D Pattern Imaging Control Solution application, enhancing advanced pattern imaging technologies including self-aligned quadruple exposure (SAQP) and extreme ultraviolet (EUV) lithography.

"Leading device manufacturers are facing extremely demanding pattern imaging specifications." Oreste Donzella, Chief marketing Officer of Kola-Tencor, said: "To address errors in pattern imaging, chip manufacturers need to quantify process changes, distinguish the causes of the changes and address the root cause of the problem. The new measurement system announced today will provide customers with critical data to help engineers implement specific corrections to the exposure machine in the lithography process, as well as process improvements in etching, film and other process modules. "We introduced new systems for stack measurements, patterned wafer geometry, optical critical dimensions and real-time temperature measurements that were critical to advancing 193i multiple exposure performance and early EUV lithography baseline data collection."

Using a new optical system and new measurement graphics, the Archer 600 extends image-based overlap error measurement technology to help advanced logic circuit and memory chip manufacturers achieve overlap errors of less than 3nm(sub-3nm). The innovative ProAIM™ graphics technology tolerates greater process variation and improves the correlation between the stack error of the measured graph response and the stack error of the device itself, enabling more accurate stack error measurement. The Archer 600's new optical technology, including a brighter light source and polarization module, provides more accurate stack error feedback and control at different process layers, from thin to opaque barriers. With increased production capacity, the Archer 600 can increase the sampling of stack errors, improve the ability to calibrate exposure machines and identify process anomalies on the production line. The Archer 600 system has been installed and operated by multiple foundries, logic circuit and memory manufacturers worldwide to measure the most advanced semiconductor devices.

WaferSight PWG2 provides comprehensive data on wafer stress and shape uniformity and is used to detect and match process parameters in film deposition, annealing, etching and other process processes. With a significant increase in capacity, WaferSight PWG2 can increase wafer sampling in production, helping chip manufacturers identify and repair process-induced wafer stress changes and eliminate accompanying pattern imaging and yield issues. Wafer shape data from WaferSight PWG2 can also be fed forward to the exposure machine and used to eliminate stacking errors caused by wafer stress, which is particularly important for the manufacture of 3D NAND flash memory devices where thick-film stacking technology can cause wafer distortion. With the industry's unique vertical wafer mount, WaferSight PWG2 measures the front and rear surfaces of the wafer simultaneously, providing wafer flatness and topography data to improve exposure machine focus prediction and control. WaferSight PWG2 systems have been installed by a number of technologically advanced IC manufacturers for the development of lithography controls, as well as for the optimization and inspection of various semiconductor production processes in series production.

The SpectraShape 10K optical measurement system measures the CD and three-dimensional shape of complex IC device structures after etching, chemical-mechanical polishing (CMP) and other process steps. To fully characterize the device structure, the SpectraShape 10K uses a number of optical technologies, including the new polarization capability and multi-angle incidence of the elliptic thickness gauge, as well as a new high-intensity light source for TruNI™ illumination for the reflectometer. These techniques allow the system to accurately measure many key parameters associated with FinFET and 3D NAND devices, such as CD, height, SiGe shape, and channel hole profile. The SpectraShape 10K has a higher capacity than the previous generation, which allows customers to achieve stricter process control through increased sampling, while also meeting the large number of process inspections required for multiple exposure technology. The SpectraShape 10K is favored by foundries for FINFETs and multi-exposure technology integration, and they are also used by many leading memory vendors to support advanced 3D NAND manufacturing.

With real-time measurements, SensArray HighTemp 4mm wireless chips provide temporal and spatial temperature information for advanced film processes. The SensArray HighTemp 4mm has a thinner wafer thickness than previous products and is therefore compatible with more types of process equipment, including track, strip and physical vapor deposition (PVD). In the temperature range of 20-400 °C, SensArray HighTemp 4mm measures the impact of temperature changes on process Windows and molding performance, enabling process optimization and equipment validation. SensArray HighTemp 4mm wafers have been used by several manufacturers of microprocessors, DRAM and 3D NAND for tuning and routine monitoring of thin film processes.

The Archer 600, WaferSight PWG2, SpectraShape 10K and SensArray HighTemp 4mm are combined with KLA-Tencor's 5D Analyzer® advanced data analysis system for real-time process control, It also provides a powerful tool for engineering monitoring and analysis. To maintain the high performance and productivity required for IC manufacturing, KLA-Tencor's global integrated service network provides backup support for the Archer 600, WaferSight PWG2, SpectraShape 10K and SensArray HighTemp 4mm systems.

您可能感興趣的產品

|

3104 | PUSHBUTTON RED POWER SYMBOL MOM | 9930 More on Order |

|

613 | WEATHERPROOF TTL SERIAL JPEG CAM | 7398 More on Order |

|

1485 | SOLAR PANEL FLEXIBLE 6VDC 1W | 7416 More on Order |

|

377 | ROTARY ENCODER MECHANICAL 24PPR | 5400 More on Order |

|

2556 | DIGITAL RGB LED WEATHERPROOF STR | 2232 More on Order |

|

2964 | ADDRESS LED STRIP SERIAL RGB 4M | 5814 More on Order |

|

2536 | NEOPIXEL DIGITAL RGB LED STRIP - | 6804 More on Order |

|

2485 | RGB LED WEATHERPROOF FLEXI-STRIP | 3528 More on Order |

|

2043 | ADDRESS LED MATRIX I2C YELLOW | 5274 More on Order |

|

1050 | ADDRESS LED MATRIX I2C YELLOW | 5924 More on Order |

|

2872 | ADDRESS LED MATRIX SERIAL RGBW | 4932 More on Order |

|

2570 | DOTSTAR DIGITAL LED STRIP - WHIT | 6276 More on Order |

|

3636 | ADDRESS LED STRIP 1M | 6048 More on Order |

|

2351 | ADDRESS LED DISCRETE SER WHITE | 5634 More on Order |

|

2226 | ADDRESS LED MODULE SERIAL RGB | 7272 More on Order |

|

2757 | ADDRESS LED DISCR SER RGBW 1=10 | 8340 More on Order |

|

1612 | ADDRESS LED MODULE SER RGB 1=5 | 7488 More on Order |

|

2659 | ADDRESS LED DISCR SER RGB 1=10 | 20208 More on Order |

|

4169 | FIBER OPTIC LIGHT SOURCE 1W PINK | 4320 More on Order |

|

250 | LCD ST7565 GRAPH 128X64 RGB BKLT | 3834 More on Order |

|

910 | 1.5"" TFT DISPLAY 160 X 240 | 7668 More on Order |

|

931 | DISPL OLED GRAPH MONO 128X32 I2C | 12156 More on Order |

|

1923 | LED BAR 10-SEGMENT YLW/GRN | 2286 More on Order |

|

1054 | LASER DIODE 650NM 5MW 10MM DIA | 14677 More on Order |